Seaweed Outreach and Extension Activities

Connecticut Sea Grant has dedicated a significant amount of research and extension funds to the investigation of appropriate species and methodology for seaweed or sea vegetable cultivation. This funding has resulted in the publication of several peer-reviewed journal and magazine articles, production manuals and technology transfer videos. In addition, Sea Grant Extension staff are collaborating with researchers, industry and regulators to commercialize this emerging industry.

Two species of seaweed that are approved for cultivation and commercial sale in Connecticut include the sugar kelp (Saccharina latissima) and Gracilaria tikvahaie. The growing season for sugar kelp is in the winter and spring, whereas Gracilaria grows in the late summer to early fall. Approved forms of kelp for human consumption include fresh (raw) kelp and kelp noodles. Gracilaria is only approved for commercial sale when cultivated in tanks (controlled environment).

Projects in progress include:

-

- Connecticut Sea Grant continues to provide one-on-one consultation with potential and current seaweed producers on grow-out techniques, processing, regulatory information and more.

- nutritional analysis and food safety study.

- testing for nutritional value of kelp from LIS.

- testing for various food safety concerns of kelp in LIS (heavy metals, iodine).

- an extensive consumer marketing survey of Connecticut residents on their consumption, awareness and perception of seaweed and shellfish aquaculture.

- projects to identify, conduct and establish processing protocols and guidelines for various types of seaweed products, including:

a. fresh (raw) – handling and storage

b. dried (dehydrated or desiccated) – processing and storage

To date, 10 commercial operations have permits to cultivate seaweed in Long Island Sound. Connecticut Sea Grant has contributed to seaweed aquaculture industry in several important ways:

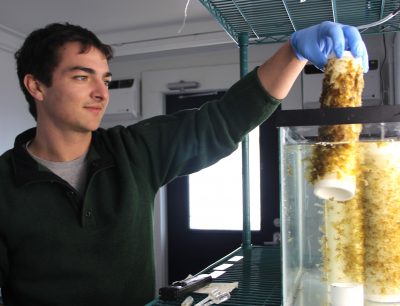

- creation of a Mobile Seaweed Research Lab. Connecticut Sea Grant obtained funds to build this lab to innovate

Clayton McGoldrick, mobile seaweed lab technician, examines a spool of seaweed growing in the lab. new techniques for sugar kelp seed production. CTSG is updating and developing educational videos on kelp seed production and researching methods of cryopreservation to preserve sorus tissue for use at the best time of year.

- co-authored a chapter on seaweed aquaculture production hazards.

- developing a guide for navigating the regulatory framework for seaweed aquaculture and post-harvesting process.

- organizing and facilitating an annual kelp industry meeting.

- co-authored a chapter on seaweed aquaculture production hazards.

- provided development funds toward the safety evaluation of kelp, allowing the first commercial grower to sell product.

- partnered with the lead aquaculture regulatory agency in the state to develop a guidance document on potential hazards associated with the production and processing of seaweeds in Long Island Sound.

- facilitated dialogue between stakeholders and regulators that resulted in the passage of legislation to benefit growers.

On Dec. 4, 2014, a seaweed regulatory meeting took place at UConn Avery Point, hosted by Sea Grant and the Connecticut Department of Agriculture, Bureau of Aquaculture. This meeting was the first to focus on discussing regulatory concerns of seaweed production and processing for human consumption in Southern New England. Regulators from NY, CT, RI and MA participated either in person or over the phone.

Current Bottlenecks:

- lack of state and federal guidelines on the production and processing of seaweed

a. Guidelines will set standards regulating sanitation of handling, storage, and processing of seaweed.

b. U.S. Federal Drug Administration considers seaweed as GRAS (Generally Recognized as Safe) when only used only as a spice. - lack of available markets for seaweed

- lack of large-scale commercial processing facilities for non-food commodities

- lack of consistent commercial seed-string supply

For information, contact:

Zachary Gordon, assistant extension educator, (860) 405-9105

Clayton McGoldrick, mobile seaweed lab technician

Download Business Planning for Kelp Farming, 2024 guidebook published by CT Sea Grant and UConn CAHNR. Access all all supplemental content, including spreadsheets and videos, by clicking here.

To purchase copy of Seaweeds of Long Island Sound—Second Edition, click here

Click here to download NY Sea Grant's Seaweed Food Safety Guidance

Additional Resources:

- National Seaweed Hub established by the Sea Grant network to serve as a science-based, non-advocacy resource for the domestic seaweed and seaweed aquaculture industry.

- Understanding Culinary Market Trends for Fresh Sugar Kelp, a report by Suzie Flores of the Stonington Kelp Co. and Anoushka Concepcion of Connecticut Sea Grant.

- Seaweed Raw Agricultural Commodity Hazards Guide 2025 by CT Dept. of Agriculture, Bureau of Aquaculture

- State Department of Agriculture's Seaweed Aquaculture website.

- For a copy of the Seaweed Cultivation Manual for New England, send a email to: judy.benson@uconn.edu.