Story and photos by Judy Benson

Stonington – When the sewage treatment plant on the Mystic River was upgraded in 2015, probably few residents here imagined local shellfish farmers might benefit, let alone oyster and clam growers across the country.

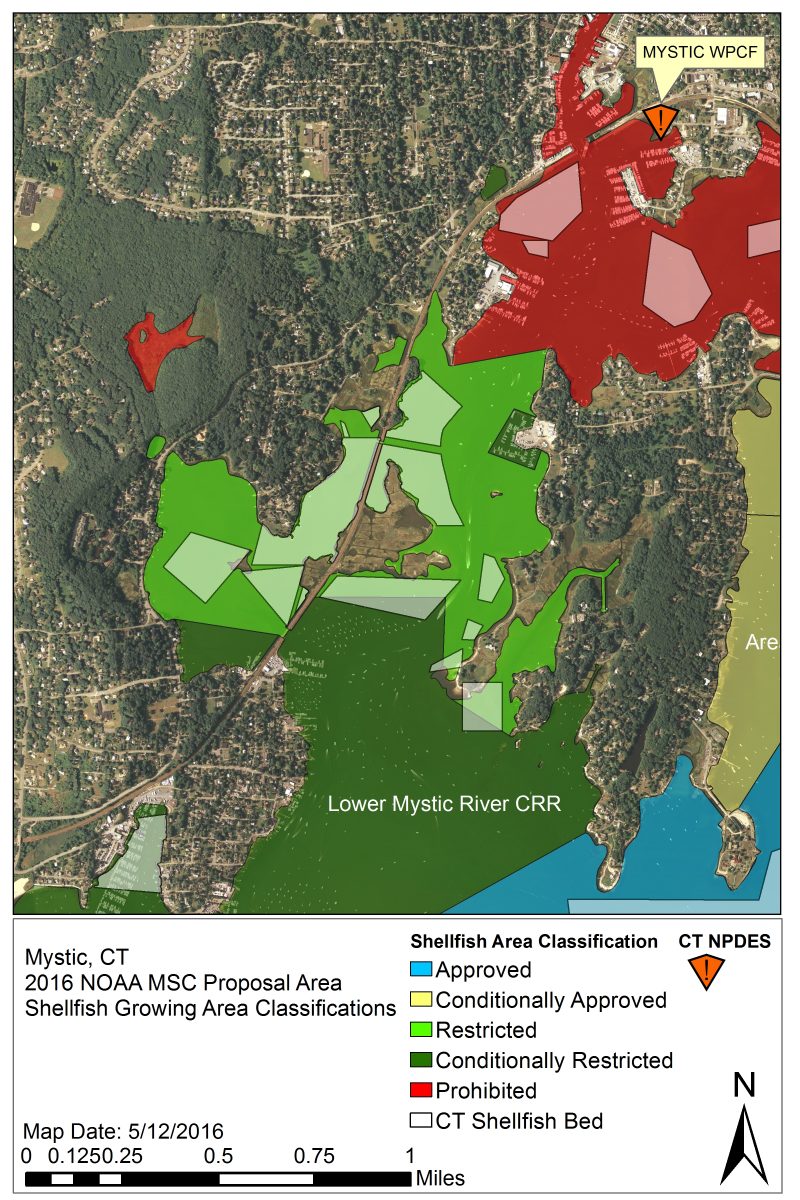

But that’s a possibility, depending on the results of a $300,000 federally funded testing project underway that could open nearly 800 acres in the river and Mystic harbor now off limits for commercial shellfishing.

“For shellfish farmers, the implications are huge, because it could increase the size of our growing areas,” said Steve Plant, who grows oysters in beds in Stonington for his company, Connecticut Cultured Oysters.

As he spoke on this sunny day in late February, he steered the Carolina skiff he uses to plant and harvest his crop toward one of a network of buoys anchored at the mouth of the river. On board with him was Kristin DeRosia-Banick, environmental analyst with the state Bureau of Aquaculture. She reached overboard to grab the line attached to the buoy, then hooked it to the motorized winch built onto the bow of the boat. Plant turned on the winch, and a few seconds later DeRosia-Banick was hauling in a dripping cageful of oysters.

“This is being done to develop national guidance documents,” she said, reaching into the cage to extract and bag a dozen or so oysters, a process she would repeat at four more sites in the river.

Earlier that morning, she had visited the Mystic Wastewater Treatment Plant with Jake Madden, lab technician from Spinney Creek Shellfish in Eliot, Me., to collect samples of treated and untreated effluent that are being tested along with the shellfish meats. It’s a routine being followed here every two weeks since fall, and will continue through June, both in Mystic and in Durham, N.H. There, a treatment plant is also located near closed shellfishing grounds farmers would like to have opened. A third testing site may be added.

“We didn’t see much happening in the fall,” said DeRosia-Banick, referring to results showing nondetectable levels of harmful pathogens in the water samples tested thus far.

“But now that we are approaching spring, we expect to see levels in the shellfish start to increase as they come out of their winter dormancy” and the oysters start feeding again.

Starting last fall with funding from the NOAA National Sea Grant program, the project involves two states, federal and state agencies, a state university and the private Spinney Creek lab where the water and oyster samples are analyzed.

“I’ll run this first thing tomorrow and get the results to them (the aquaculture bureau and project partners) by Thursday,” said Madden, after filling sample bottles on a recent Tuesday morning at the Mystic plant, then packing them on ice in a cooler for the three-hour drive to his Maine lab.

While testing protocols for harmful bacteria in water and shellfish meat samples have been well established and considered a reliable water quality indicator, they left out a crucial element needed to determine where it is – and isn’t – safe to grow and harvest clams and oysters. Viruses that can also pose a risk to human health must also be tracked, but a practical means of detecting these minute organisms had to be found. That’s where this testing project comes in. The Spinney Creek lab had successfully used the testing method to get approvals for its depuration plant – where shellfish go to purge contaminants before market – so using the same test for the potential growing areas was seen as a logical extension of the same technique.

The motivation for the project originated with shellfishermen including Plant who are part of the Noank Aquaculture Co-op, located at the mouth of the river just two miles downstream from the wastewater facility. Several of the co-op farmers work beds in the surrounding waters. Due to proximity to the wastewater plant, sections of the Mystic River and harbor that would otherwise have been optimal for oyster harvest remained off-limits for direct harvest. But as far back as 2009, shellfishermen started asking to have some of those areas upgraded.

Then after the $18 million installation of new equipment at the aging Mystic plant along with two others in town, the conditions became even more favorable for expanding the shellfishing into areas closer to the plant. Among the most significant changes to the Mystic plant was the addition of ultraviolet light treatment, a major advance from the chemical processes previously used. The upgrades had been done mainly to improve nitrogen removal and bring the plants up to state standards, but did the cleaner waters being discharged also offer the new opportunity shellfishermen had been waiting for?

“In the Mystic River, the shellfishermen were very interested in having areas upgraded to expand the areas they could use to grow shellfish,” said Tessa Getchis, aquaculture extension specialist at Connecticut Sea Grant, which is working with the state aquaculture bureau on the project. “The state spent several years testing the water throughout the Mystic River. The farmers knew the water quality had improved and wanted to find out if those areas could be opened.”

Getting an answer to that is no simple matter. The quest began with bacteria and dye testing study to track the flow of the plant’s discharge into the river. Those showed the waters once prohibited for shellfishing now meet public health safety standards for bacteria. The painstaking process of figuring out if harmful viruses were present came next. With the early promising results, the potential that the testing project could benefit shellfishermen both locally and nationwide became a source of pride and excitement for those involved.

“This is the first time this method has been use for this specific purpose,” Getchis said.

For the water testing part of the project, samples are collected at the plant at three points in the treatment process, from the cleanest to the dirtiest. The cleanest samples come from a channel at the end of the process, where low-level radiation from an array of UV lights sterilize the water just before discharge. The UV lights replace chemical chlorination, said Gerald Miner, chief plant operator.

“It’s better for the environment, and there’s a cost savings, because the electricity is cheaper than the chemicals,” Miner said.

On his visits to the plant, Madden starts at 9:30 a.m., making note of the volume of water flowing through the plant, the amount of recent rainfall and the turbidity – a measure of suspended particles.

“And then we do it twice more each time, at 10:30 and 11:30, every other week,” Madden said.

The samples sent to the Spinney Creek lab are then tested for indicator viruses that often exist when other harmful viruses that are harder to detect are present. Using these indicator viruses to screen for illness-causing viruses and then using this information to decide whether shellfish growing areas near wastewater treatment plants can expand is a unique application of this technique, Getchis said.

“We’re trying to make sure this tool works,” she said.

Though test results thus far show favorable results, the samples must be taken through all four seasons, because of changes that occur in shellfish metabolisms with temperature. Possibly as soon as 2019, the data will be presented to the Interstate Shellfish Sanitation Conference, the federal-state-industry body that decides on rules for commercial shellfish. Ultimately, it could be adopted as an approved method to be used by shellfish managers working under National Shellfish Sanitation Program regulations.

If the guidance is adopted, individual states would then decide whether to use it in their own coastal areas to determine whether new shellfishing grounds could be opened.

“It will be a state-by-state decision,” DeRosia-Banick said.

In the meantime, the Mystic River growers will have to remain patient. The state Bureau of Aquaculture needs to collect months more of data, then do the analysis and present findings to the interstate panel before it’s ready to make decisions on whether to expand the growing areas. But if some or all of the five areas in question are opened, the local shellfish farmers will gain access to some of the most easily accessible and nutrient rich growing areas – and potentially benefit their fellow shellfishermen in other coastal areas at the same time.

“These are prime farming areas they’d like to use to grow their shellfish,” Getchis said.

Added Plant, the oyster farmer: “It will make how we can do things way easier.”

Judy Benson is the communications coordinator for Connecticut Sea Grant. judy.benson@uconn.edu